HYDRAULIC COUPLINGS

CONSTANT

FLUID FILLING

1TO 1,0000 HP0.73 TO 736 KW Former Isotta Fraschini Production

A project by

THE PRODUCT

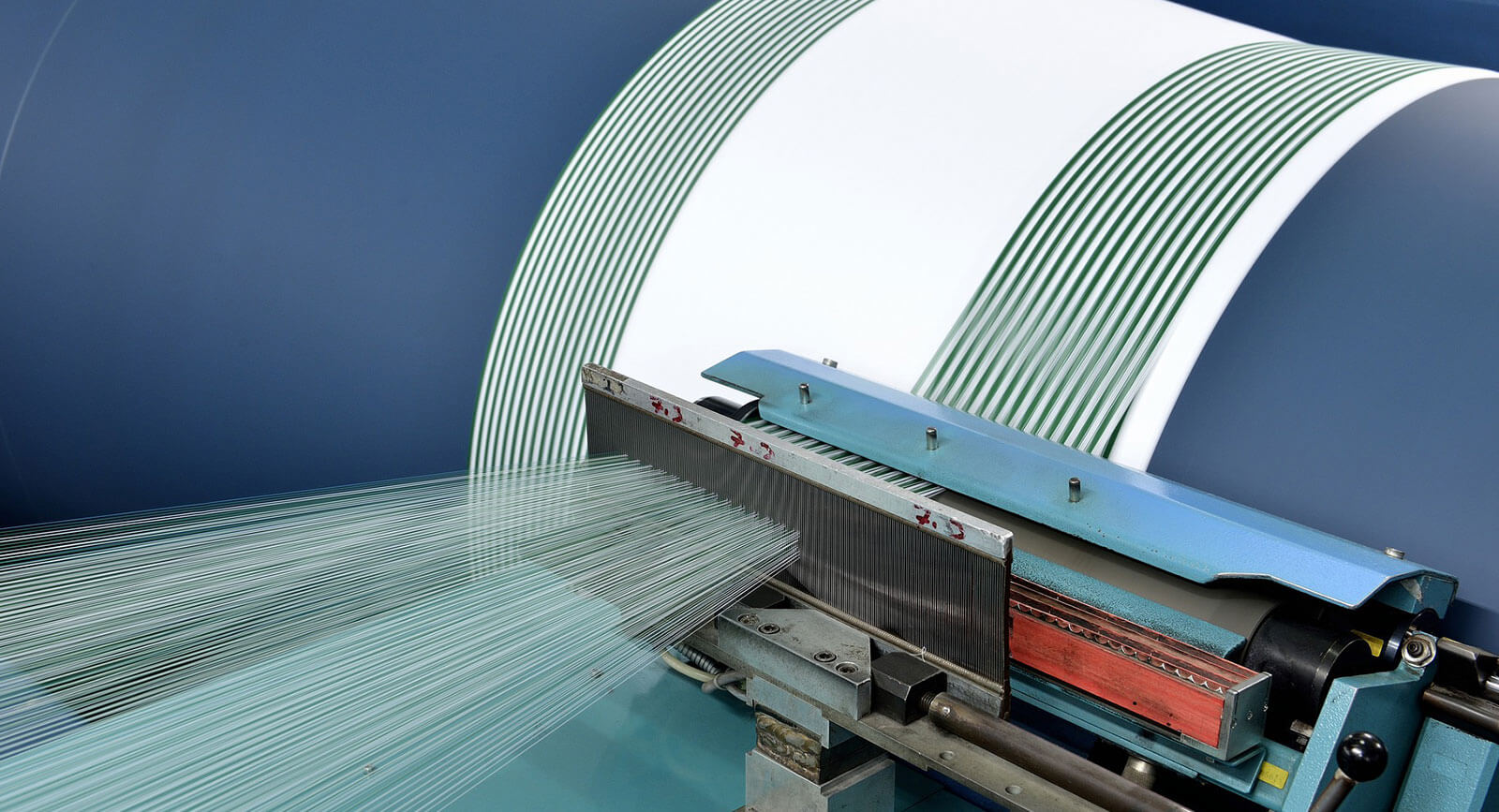

Constant filling hydraulic couplers, also known as "Fluid Couplings" have a very wide field of application

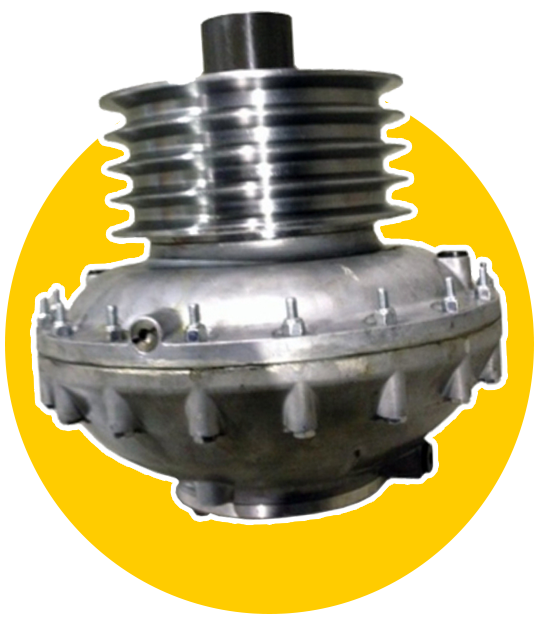

The fluid coupling is of a very simple design and construction, consisting of two opposed impellers connected respectively to driving and driven members and the oil which fills the coupling transmits the torque and lubricates the running parts.

IMPIEGO

- driven by electric motor or Diesel engine.

- on many kinds of driven machines including cranes, coveyors, mixers, crusher, lift trucks, agitators, ventilators, etc

- in mechanical, chemical, textile, mining, naval and other industries

- in dusty or damp conditions-as well as out in the open.

- in any mouting position.

ADVANTAGES

- facilitate startlng

- gradually accelerate the driven machine

- protect against overloads

- absorb torsional vibration

- act as a torque limitor

- allow direct-on-line starting tor the motor in the majority of cases. Allow the use of sqirrel cage motor where splip-ring motor would normally have to be used

WORKING FEATURES

These two impellers when running act as impeller and runner such that the coupling works as a turbine which quadratic torque characteristics dependent upon the number of revolutions.

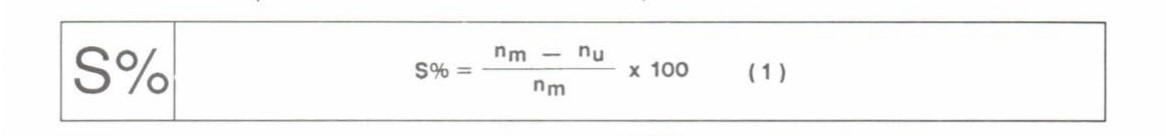

The fluid vector losses, because of the friction, transforms into power, less is representable in the slip with the formula which:

Where:

Nm = motor speed (rpm) and Nu = output coupling speed (rpm)

Where:

Nm = motor speed (rpm) and Nu = output coupling speed (rpm)

When the coupling is interposed between motor and driven machine the driving torque of the starting motor (Cm) serves to accelerate the primary part of the hydraulic coupling In such conditions the motor starts and accelerates as if it was idling and reaches with great easiness 70-80% of its working speed

The coupling can be run in either direction of rotation and can also be run in the opposite direction where the runner becomes the impeller and viceversa without modification

The coupling has the same performance characteristics which ever direction of rotation. This the coupling combines flexibility and reliability of operation with minimal wear and maintenance.

OPERATING CALCULATIONS

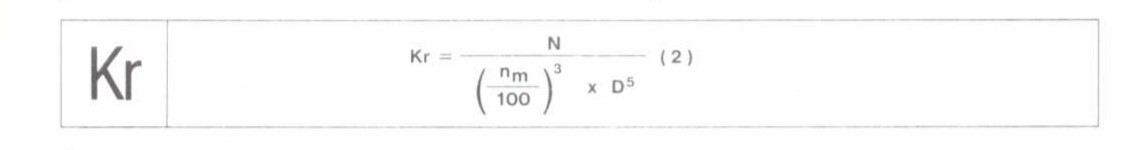

The operating principle is based on the following formula:

Where

Where

N - horse power transmit ted by the coupling

Kr - experimental coefficient at full speed

Nm - motor speed in r p m.

D - outside diameter in metres of the working circuit (The number 14, 18, 21, etc. corresponds to diam. D in centimeters)..

The Kr coefficient value normally has to be contained between Kr = 1 (minimum tor the larger couplings like the 70 size) and Kr = 5 (maximum tor the smaller couplings like the 18 size).

When Kr is known, the slip can be evaluted by experimental curves.

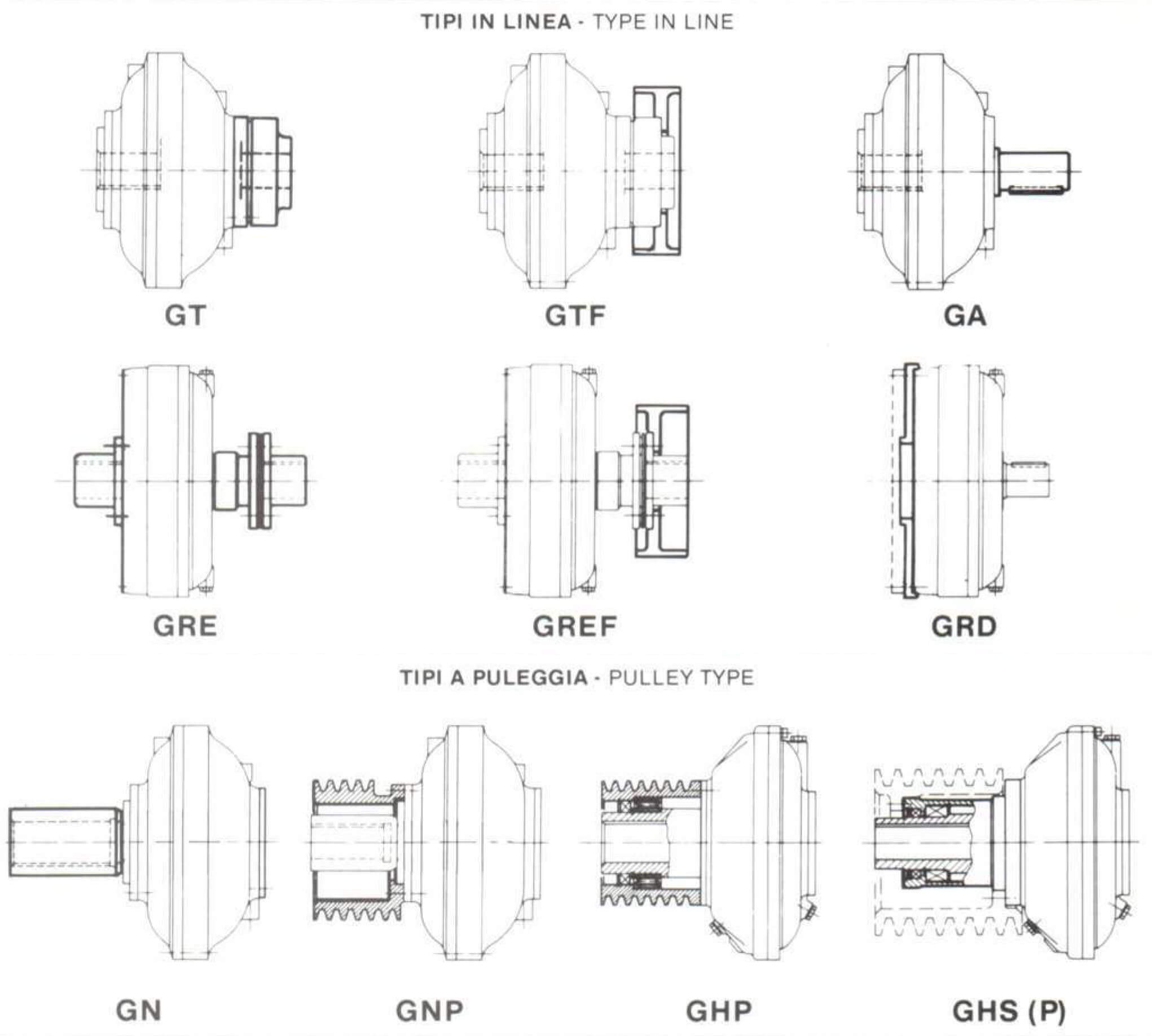

SOME SOLUTIONS

HYDRAULIC COUPLINGS GT

HYDRAULIC COUPLINGS GNP